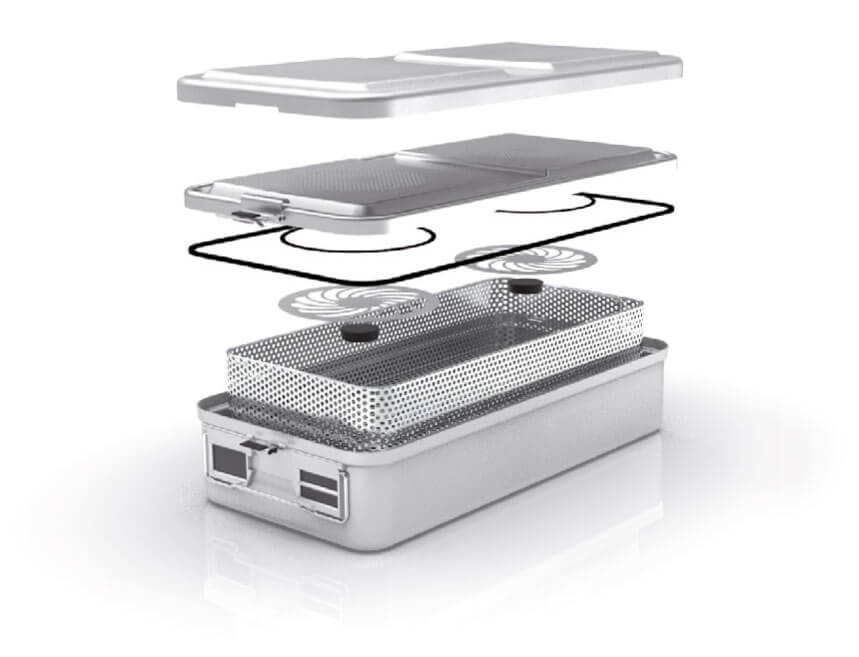

REUSABLE STERILIZATION CONTAINER IS A COMPLEX PACKAGING SOLUTION AND REQUIRES THAT ALL IT’S PARTS WORK FLAWLESSLY TOGETHER.

FROM LID TO BOTTOM, FROM FILTER TO GASKET.

REUSABLE STERILIZATION CONTAINER IS A COMPLEX PACKAGING SOLUTION AND REQUIRES THAT ALL IT’S PARTS WORK FLAWLESSLY TOGETHER.

FROM LID TO BOTTOM, FROM FILTER TO GASKET.

What happened with the container after it’s being used multiple times?

Do we still have the same performance and reliable microbial barrier?

Where is the risk?

If gasket integrity has been compromised, reusable container shall not be used according to manufacturer’s instructions

What does the EN ISO 11607-1 say about critical points for reusable containers?

Considering the visual check as the only available method to control integrity, can we rely on this according to EN ISO 11607?

How we can be sure that containers guarantee protection without any compromises?

Here is an easy test that gives the answer immediately.

1

°

Pour water in the bottom of container until a level of 5 mm is reached

![]()

2

°

Close the lid

3

°

Wipe the outside of container with a towel

4

°

Put the container on its edge standing vertically

5

°

Verify the presence of leakage after 30 seconds

6

°

Change the side, running the container along its edge

7

°

Repeat the test after turning the lid around

If water can find its way through air certainly too

and it means a risk of contamination.

Have you tried the Water Leak Test?

Share with us the results: